AI for Operators and Engineers

As an operator or engineer, you’re not looking for hype – you’re looking for tools that make your job easier, not more complicated.

AI in manufacturing is about giving you fewer headaches, more control, and the information you need to make quicker, better decisions on the line.

AI That Understands the Realities of Your Role

We know the reality: the SCADA room lights up with endless alarms. You’re juggling complex machinery that demands constant attention, and when something goes wrong, you’re expected to diagnose and fix it under pressure with tools that are reactive, not proactive.

How AI can assist you as an Operator

- It can reduce false alarms and highlight only the most important alerts.

- Spot patterns across thousands of signals.

- Summarise what’s likely causing issues before they affect output or quality.

Key benefits for Operators

Operators we speak to often say the most valuable innovations reduce workloads, such as when a system takes on the heavy lifting of monitoring, analysis, or prediction. The goal isn’t to drown you in more dashboards. It’s to provide clearer insight from the systems you already use.

How to implement AI in your role

And most importantly, AI is most useful when it’s shaped by your feedback. When implementation starts with a real conversation about your workflow and pain points, the result is a toolset that works the way you do.

Less noise. More clairty.

Every shift brings alarms, endless data points, and the pressure to react fast. But when alerts fire off for every minor fluctuation, it’s hard to know what really matters.

AI tools built for the shop floor help cut through the noise and prioritise the alerts that need action and flagging issues before they become breakdowns. That means less firefighting and more control over your process. Whether you’re in the SCADA room or out on the line, AI can work in the background to support you, not distract you.

Learn how AI fits into your daily workflow in The Road to AI a practical introduction to what AI can (and can’t) do for manufacturing teams like yours.

Make the Data Work for You

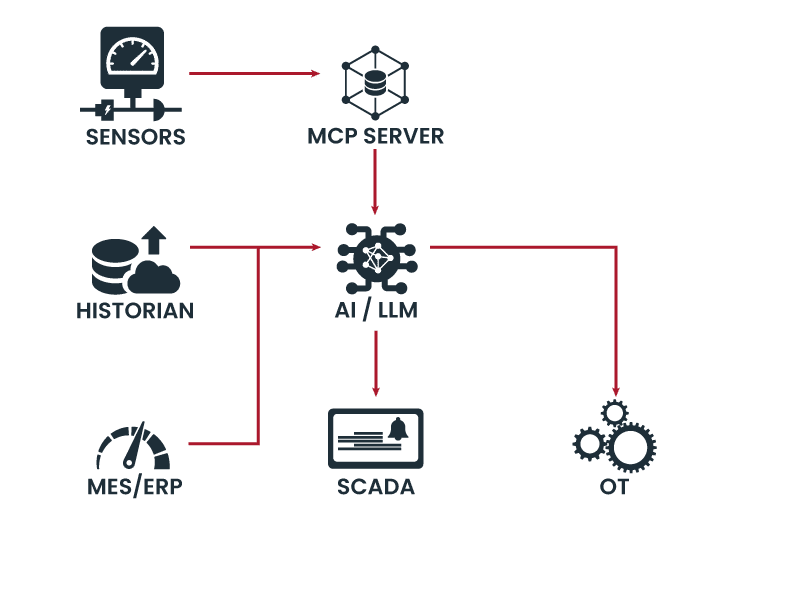

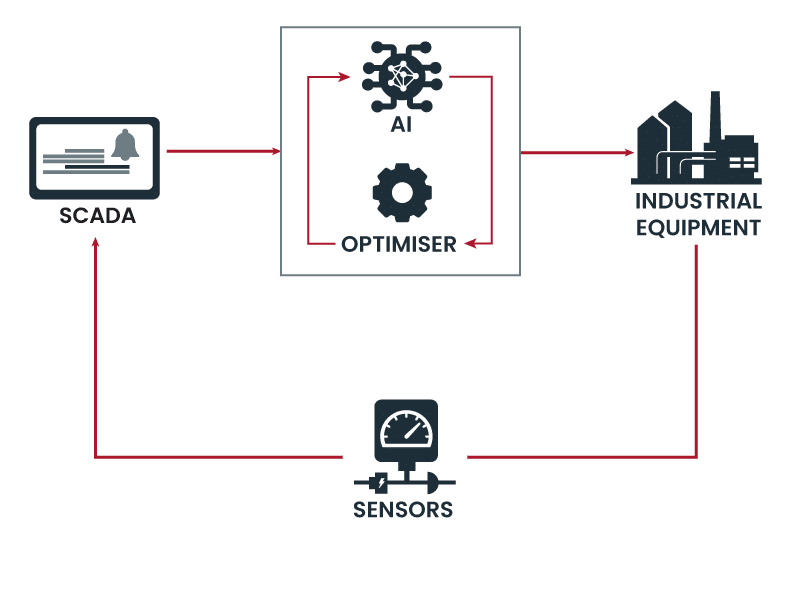

You’re surrounded by data – from sensors, machines, line systems, and controls. But unless that data is structured and connected, AI can’t do much with it.

The good news? You don’t need a data science degree to start making it useful. By breaking down silos and creating a common data layer, AI tools can start surfacing the answers that matter – like why your yield dropped yesterday, or why line 3 keeps hitting downtime. It’s not about building something new – it’s about unlocking the value of what’s already there.

Find out how to prepare your data the right way in Is Your Industrial Data Ready for AI? – a simple guide for engineers and operators.

AI vs. ML – What’s the Difference on the Shop Floor?

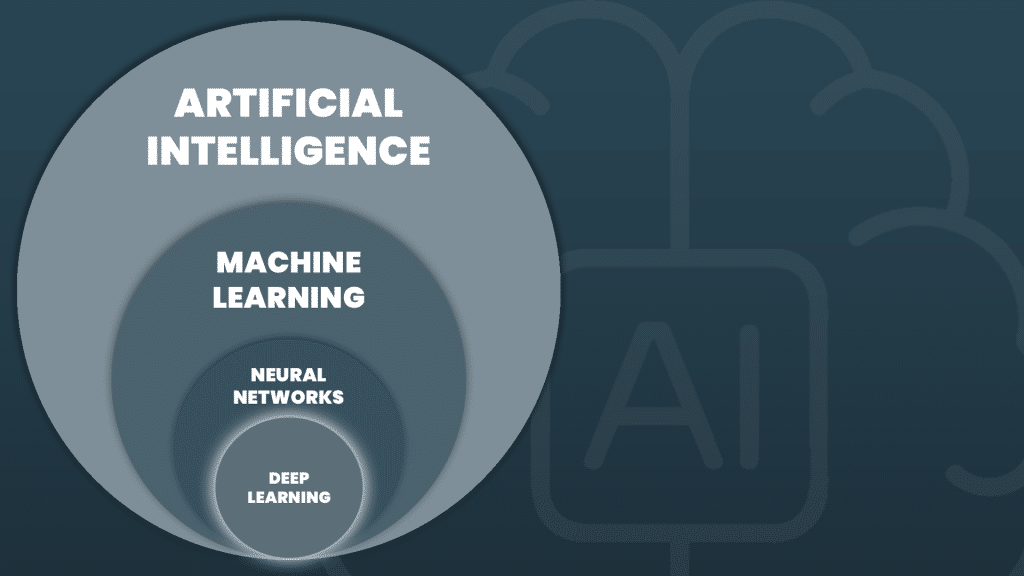

You’ve heard the buzzwords: artificial intelligence, machine learning, predictive analytics… but what do they actually mean for your job?

At the operator level, the difference matters less than what they can do. AI can automate repetitive tasks, while machine learning can find hidden patterns in performance. Together, they turn your plant’s noise into insights—telling you what’s likely to go wrong, when, and why.

Understanding the difference helps you ask better questions and get more from the systems around you.

Brush up on the basics with Artificial Intelligence vs Machine Learning – and see where each fits into industrial operations.

See It in Action: Real AI Use Cases

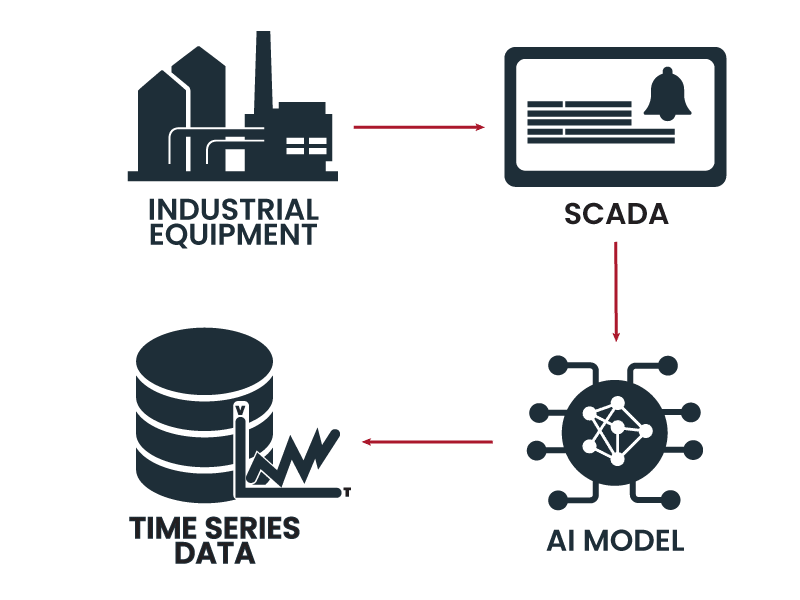

AI isn’t science fiction – it’s already helping operators work smarter across a wide range of industries. From predicting pump failures before they happen, to identifying the root cause of quality issues without hours of trial and error, AI is changing how problems are solved.

Imagine a tool that automatically flags which variable is dragging down yield, or alerts you when equipment starts trending toward failure. These aren’t future promises – they’re real examples already deployed on live systems, saving teams time and stress every day.

Predictive Maintenance

Energy Optimization

AI Assistance via MCP