Industrial AI for C-Suite

Scale Smarter. Make AI Your Competitive Advantage.

How can you, in the C-suite, leverage AI to unlock performance across plants, teams, and systems?

AI isn’t just a buzzword or a technology trend, when understood and applied correctly, with well-structured data, it’s a lever for growth, competitiveness, and resilience. To achieve true value from AI means embedding intelligence into the core of your operations across every plant, system, and decision-making process.

AI That Aligns Strategy with Execution

Efficiency, profitability, and sustainable performance are the goals shared across every level of your operation; the only difference is scale. While a plant manager focuses on one plant’s recovery rate or throughput, you need to see how performance trends are playing out across multiple sites, regions or business units.

The power of AI

The power of industrial AI is in making those insights visible, timely, and actionable.

AI-driven systems can surface which lines are dragging down performance, which assets are nearing failure, and which process changes are driving margin improvement—all without relying solely on human interpretation or static reports.

Leverage what you already have

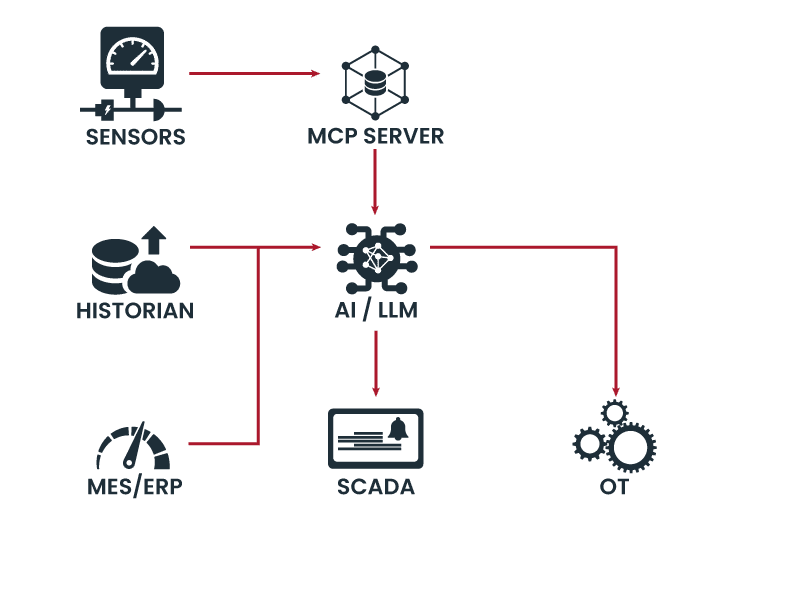

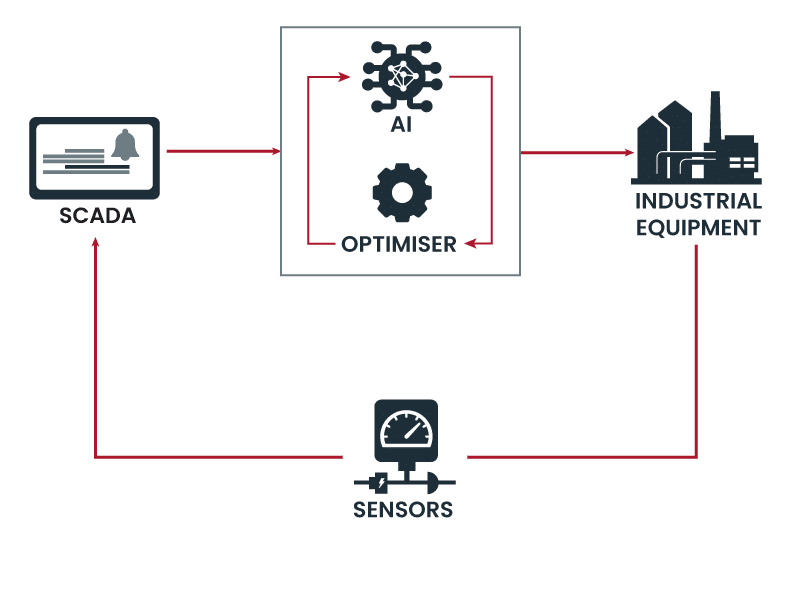

You don’t need to replace your infrastructure to make AI work. With the right approach, AI tools can integrate with your existing SCADA, MES, and data historians to deliver fast ROI while preserving operational stability.

How to be competitive

What’s more, as AI capabilities expand with the introduction of natural language tools and predictive optimisation your teams will gain access to insights without needing data science expertise. That means faster adoption, better results and greater alignment between strategy and operations.

Enterprise Performance, Driven by Real-Time Insight

You don’t just want more data, you want to know what’s working, what isn’t, and where to intervene. Industrial AI platforms enable near real-time comparison across sites, assets and teams.

Whether you’re tracking yield, energy consumption or quality consistency, AI brings visibility across your entire network of operations to make the your next decision faster and better informed.

See how it all fits together in The Road to AI, with a breakdown of the technologies shaping modern industrial performance.

Build a Scalable AI Foundation

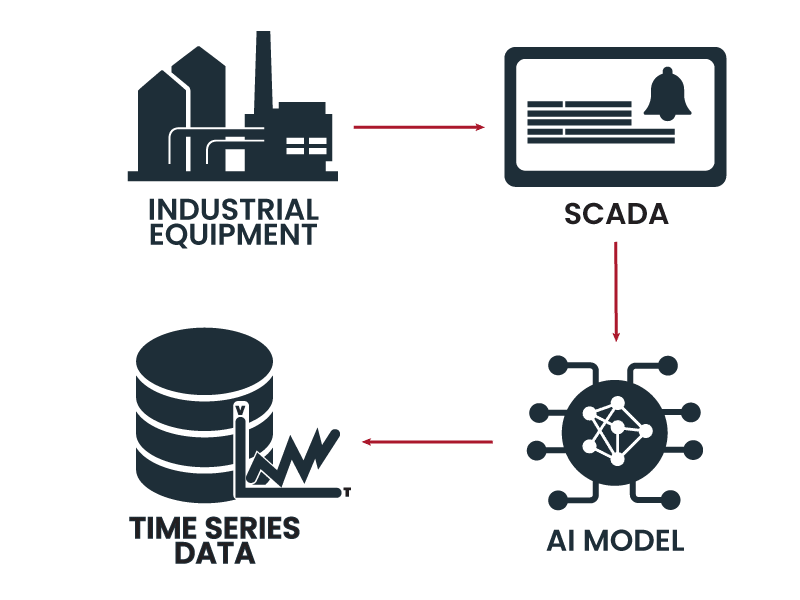

The foundation of any successful AI rollout is data. And for most organisations, the challenge isn’t collecting data but connecting and contextualising it.

From legacy historians to SCADA systems, getting your data AI-ready means building a layer of integration that can span sites, vendors and formats.

Once that’s in place, the ability to scale AI across plants becomes not just possible, but powerful.

Explore how to evaluate your readiness in Is Your Industrial Data Ready for AI?, and take the first step toward enterprise-scale AI.

Understand the Tools that Power Transformation

AI. ML. Predictive analytics. Prescriptive controls. You’ve seen the terms, but which matter most?

For strategic decision-makers, it’s important to separate substance from noise. AI automates or optimises actions. ML uncovers hidden patterns.

When aligned with operations, these tools reduce losses, extend asset life, and elevate your people’s effectiveness without requiring a full digital transformation in one go.

Cut through the jargon in Artificial Intelligence vs Machine Learning and understand what will move the needle in your business.

See Strategic Impact in Practice

The results speak volumes. AI systems have helped manufacturers reduce energy costs, extend equipment uptime, and uncover hidden causes of quality loss all without large-scale changes to plant infrastructure. From forecasting maintenance windows to optimising recovery rates, these are the improvements that impact more than just engineering KPIs.

See what AI can deliver in Industrial AI: 3 Use Cases, and how leading operations are building advantage through smarter systems.

Predictive Maintenance

Energy Optimisation

AI Assistance via MCP