Industrial AI for Plant Managers

Turn Operational Data Into Strategic Results

How can you leverage industrial AI as a Plant Manager? You’re not in the control room – but you need to understand it. You’re responsible for hitting recovery rates, reducing downtime, increasing output, and meeting sustainability or efficiency targets.

That means knowing not just what’s happening – but why. And that’s where industrial AI steps in.

Insights that Drive Daily Decisions

You already track KPIs across your plant. But manual root-cause analysis can be time-consuming and inconsistent. You’re often left reacting to daily reports, trying to interpret long chains of data or chasing unexplained drops in performance. Industrial AI helps you move from reporting to understanding faster while reducing workloads.

Where to start as a Plant Manager

By surfacing key contributing factors and identifying recurring patterns, AI systems enable you to pinpoint inefficiencies, spot emerging issues, and act with confidence.

Whether it’s a quality dip on Line 2 or increasing power usage on a filler, AI tools help cut through the noise to show you what really matters.

Key benefits: Actionable insights

Managers and C-Suite leaders often want the same thing: to improve performance and profitability. The difference lies in scale and focus. At the plant level, AI needs to give actionable insights across multiple areas of responsibility – whether that’s energy use, downtime, quality, or throughput.

When done right, industrial AI doesn’t just help you hit targets. It gives you the visibility to find better ones.

From Data Overload to Targeted Action

Your plant is full of data – from lines, sensors, and processes – but how much of it helps you make smarter decisions?

AI allows you to automatically identify key contributors to underperformance, show trends across shifts or equipment, and support faster resolution of recurring issues.

Instead of waiting for end-of-day reports, you get timely, focused insight when you need it. Whether it’s boosting output or reducing scrap, AI helps you align your data with your daily goals.

See how this kind of transformation starts in The Road to AI, with clear examples of how AI fits into plant-level operations.

Get Your Plant AI-Ready

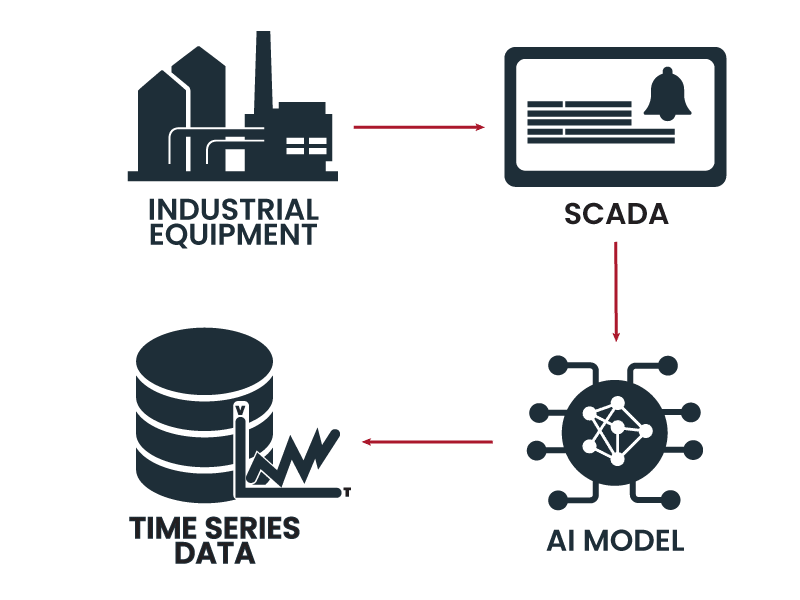

Before AI can unlock insights, your data needs to be accessible, structured, and connected across systems.

For many plant managers, legacy systems or siloed platforms are a barrier. The good news: you don’t need to start from scratch.

By layering AI-ready structures over existing systems and improving contextualisation, you can begin extracting real value. This doesn’t just support AI – it also improves the quality of dashboards, reporting, and team collaboration.

Learn how to get your site’s data infrastructure ready with Is Your Industrial Data Ready for AI?

AI vs ML: What’s Behind the Buzzwords?

You’ve heard both terms thrown around – often interchangeably. But understanding the difference helps you evaluate technologies more critically.

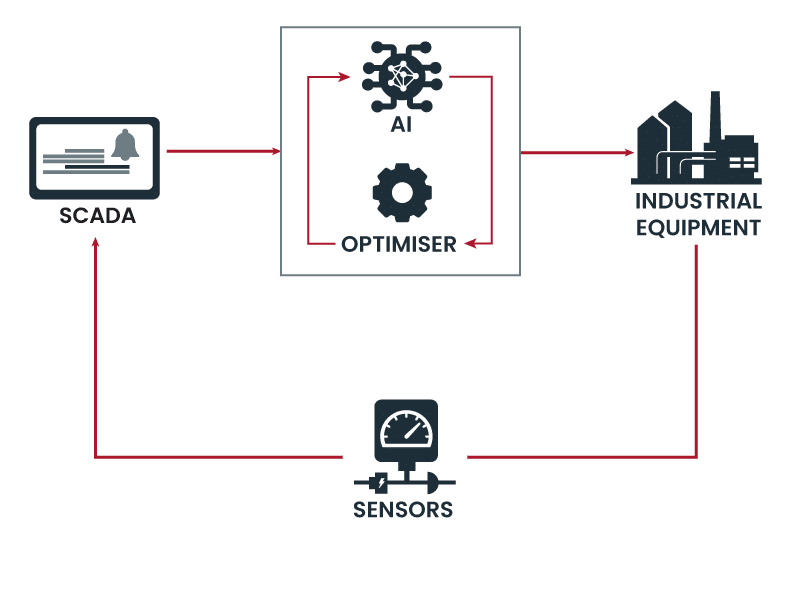

AI refers to systems that can make decisions or automate actions, while machine learning focuses on pattern recognition and prediction. In practical terms? ML helps identify root causes or trends, while AI can automate parts of the response. Both are critical tools in improving process stability, product quality, and energy efficiency.

Demystify the terms in Artificial Intelligence vs Machine Learning, with examples grounded in real plant operations.

Real Use Cases. Real Results.

It’s one thing to talk about AI – it’s another to see what it does in practice. From identifying which variables are dragging down quality, to predicting asset failure days in advance, modern industrial AI tools deliver fast ROI.

Managers can now access self-service analytics that visualise trends across multiple lines or compare shifts – without calling in data specialists. These tools don’t replace your judgment – they make it sharper.

Predictive Maintenance

Energy Optimisation

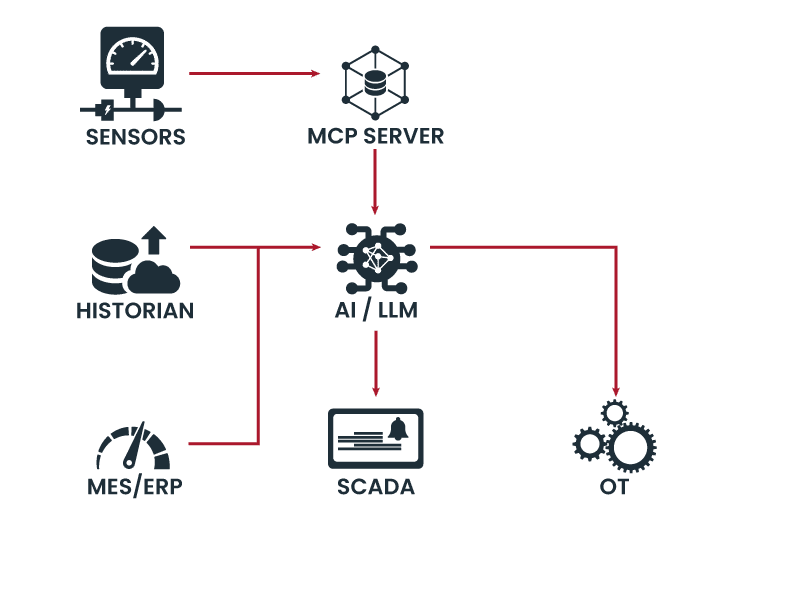

AI Assistance via MCP