Democratization of Data Analysis

“This story was originally published by Steve Pavlosky GE Digital

and has been republished here with permission.”

What does the tag ALB_BLDG1_L1_M47_DISPUMP1_RPM mean?

How do we overcome the challenges around deriving real value from data that is collected? The first step in turning data into information is creating context for the data.

Whether data is from an HMI/SCADA system (collected from PLC memory locations), time series and alarm and event data from a historian, or IIoT sensor data, industrial data is typically identified by a tag name. People that work with data everyday may understand how these “tags” correlate to signals coming from the plant equipment or other sensors. The problem is that set of people represents a small percentage of the people that could potentially get value from the data.

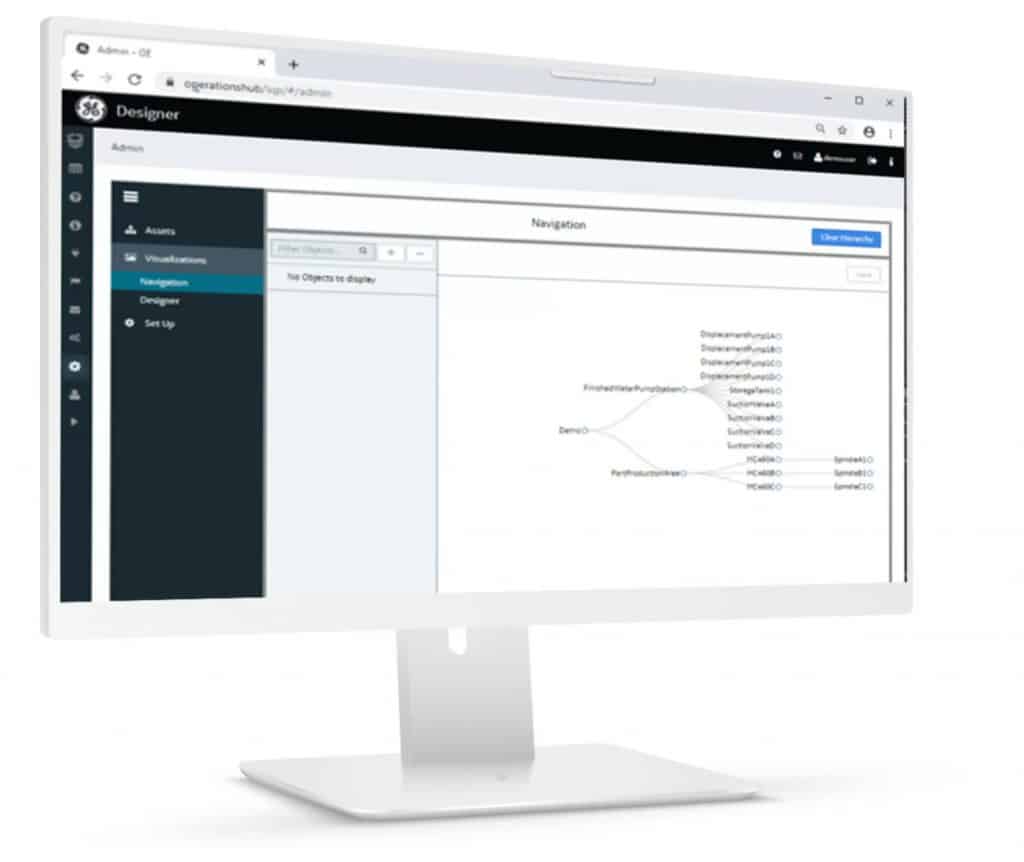

The answer is to create a mapping between the tag data and a representation of the machine, line, plant or enterprise – called an asset model. Any user who wants to know the value of any specific sensor (such as RPMs of a pump) can find the specific pump in the model and see the data values associated with the pump, RPMs in this example.

Asset modelling today includes the ability to create standard object types (think templates) that include the standard set of information associated with a type of equipment. Having standard object types (templates) that can be referenced for each similar piece of equipment further enhances users’ ability to understand the plant equipment. Comparison of the parameters associated with multiple examples of a given equipment type becomes simple.

So, what does ALB_BLDG1_L1_M47_DISPUMP1_RPM mean? Probably only a few people know the answer. However, almost everyone can understand what the RPM parameter for the discharge pump number one on Mixing Machine 2 in Building 1, Line 1 in Albuquerque means. And if they want to compare the behavior of Discharge Pump 1 and Discharge Pump 2 – no problem. Context makes all the difference.

Putting information (data in context) in the hands of every user

One of the fascinating impacts of the age of IoT is the merging of two trends – a workforce of digital natives that are comfortable with technology, and technology toolsets that simplify the task of creating applications that show operators the right mashups of information from various business systems on their device of choice.

The newest generation of web technology-based application development tools are designed with the following capabilities:

- Drag and drop, code-free application building

- Mobile operator support, including responsiveness to device type (desktop, tablet, phone, smartwatch)

- Asset model context for data and analysis tools

- Security features allowing control of data visibility and application functionality (read only vs. read write, for example)

- Unlimited developer and runtime licenses

The combination of easy to use tools and data in context of an asset model has created an opportunity for individuals to create web-based applications that show plant data in the way they want to see it. Individuals can build mini applications (web pages), link them together, and share them amongst their peers. Since the mini apps are asset model aware, other users that manage similar assets elsewhere in the organization can use the mini apps unchanged by navigating to the asset they manage within the context of the app and asset model. All of this is possible within the network and IT security infrastructure that exists within plants today.

This ability for the individual to explore, create, test, modify, and share tools that enable better outcomes represents a sea change from the current paradigm where system design is managed by a few “experts”. DCS’s, HMI/SCADA’s, Historians, and even Operator Interfaces – all require a level of expertise, access to development tools, and change management processes. For these operational systems, the engineering practices that are applied to systems that interact with plant equipment. The new generation of tools is designed to interface with these source systems and other data sources (smart sensors, other business systems) to provide information which enables better decision making in a novel way.

For companies looking to accelerate their digitization journey and take advantage of the skills of the new digital native generation of employees, these new web technology based tools can play a key role in achieving these goals.

/ Steve Pavlosky

Principal Product Manager, Proficy Historian and Data at the Edge, GE Digital

Steve Pavlosky is the Principal Product Manager for GE Digital’s Proficy Historian and Data at the Edge program. With more than 30 years serving in automation and industrial data management, Steve is an Industrial Internet pioneer and firm believer in the value and power of data. His career spans the introduction of GE’s CIMPLICITY HMI/SCADA software to leading the company’s edge-to-cloud connectivity device portfolio. Having worked with hundreds of customers, Steve is passionate about enabling organizations to get the most performance and reliability from their assets – which starts with secure and efficient collection and storage, contextualizing asset data, and distributing data to the users and applications that derive value from the data.